Polytetrafluoroethylene (PTFE) has excellent heat resistance, corrosion resistance and good electrical insulating properties, it is a kind of important matrix composite materials for sliding friction parts. But due to low hardness, poor wear resistance of pure PTFE, the modification of PT FE in recent decades to a lot of researches, found in adding graphite, PTFE Mo S2, copper powder, glass fiber, carbon fiber, etc., can significantly improve the strength, hardness and wear resistance, etc. Many studies have shown that mixed filling materials than single filler material to improve the friction and wear properties of PT FE is better. Graphite is a good solid lubrication materials, filling in the PTFE graphite can further improve their tribological properties, graphite filled PT FE has become more widely in engineering application. Nanometer materials is the excellent performance of new materials developed in recent years, due to the nanometer material has good plasticity and toughness, its strength and hardness is higher than ordinary coarse grain materials 4 ~ 5 times. Current research on modification of polymer with nano materials much attention, in recent years the domestic existing unit to carry out this work. The author of SiO2, TiO2, Al2 O3 three different nano materials mixed with graphite filled PTFE composite material has carried on the friction and wear performance test, comparing their tribological performance, they wear mechanisms are also discussed.

Test method

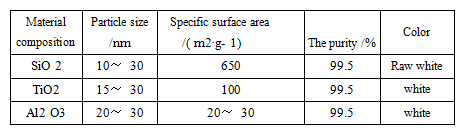

The PTFE average particle size is 50 microns, graphite’s particle size is 1. 5 ~ 30 microns, the performance of three kinds nanometer materials of SiO2, TiO2, Al2 O3 are shown in table 1. The three kinds of nanometer materials respectively by 10% and 5% mass fraction of graphite join the PTFE, according to the following process to make different nanometer materials filled PTFE composite material specimen:

PTFE+ nano material – graphite→ mechanical stirring blending→compression molding→blank products→sawing→polish→specimen

Table 1 The performance of the nano materials

M M – 200 type friction and wear testing machine is adopted to improve the friction and wear test, the rotating speed of 200 r/min, the conditions of dry friction sliding, couple of 45 # steel ring, the surface roughness Ra to 0.08 ~0.12 microns. Wear mass loss of samples are measured under different loading (with one over ten thousand of the photoelectric analytical balance), and the coefficient of friction. Use JMS – 6300 scanning electron microscope to observe and analyze (SEM) of nanometer mixed with graphite filler composites wear surface morphology, and adopt Brinell hardness tester to measure hardness, load is 62. 5 N, loading time is 60 s.

Test results and discussion

Wear performance

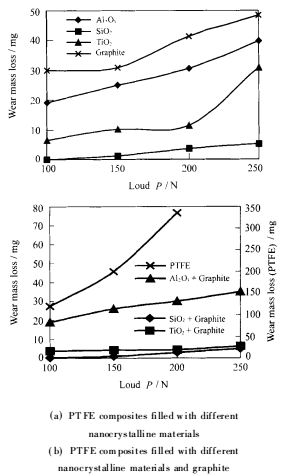

Figure 1 shows the three kinds of nanometer materials and their mixed with graphite filler PT FE and the grinding quality of the pure PTFE under different load loss. Can be seen from figure 1, filled PTFE composites wear mass loss is much smaller than the pure PTFE, nanometer materials and their mixed with graphite filler PT FE wear resistance than pure graphite composite mixed filling PTFE composite material is much better than that of nanometer materials and their mixed with graphite filler PTFE composite material with high wear resistance, which can effectively improve the wear resistance of PTFE. Also suggests that single graphite filler of PTFE to improve the wear resistance of the result is bad, are not equal to its single nanometer material of PTFE mixed with graphite filled PTFE composite material, may be the graphite as nanometer materials can have the effect of effective support load, and graphite played a good lubricant and can form transfer film on the friction process to reduce wear materials, to make the nanometer materials and their mixed with graphite filler of PT FE composite material has good abrasion resistance. Can be seen from the figure 1 (b), three kinds of material mixed with graphite filler to PT FE abrasion resistance is different, the influence of the nanometer SiO2 nano TiO2 – graphite – graphite, the two materials on wear resistance of PTFE increased more, especially nano SiO2 – very effective to improve the wear resistance of PTFE and graphite materials and Al2 O3 – graphite material with nano SiO2 – graphite, TiO2 – graphite material, compared to the improve the wear resistance of PTFE is relatively less, and also can be seen from the figure 1 (a), a single nanometer SiO2 is very effective to improve the wear resistance of PTFE, but trials found that SiO2 / PTFE composite materials prone to cracking phenomenon, the reason is worth further exploration in the future.

Figure 1 The relationship between wear mass loss and the load of nanometer materials and its mixed with graphite filler material filling PTFE.

Figure 1 also shows that PTFE and three kinds of nano and its mixed with graphite filled PTFE wear mass loss increase with the increase of load, PTFE wear mass loss increased faster, and the wear mass loss of filled PTFE composites increase more gently, and three kinds of nanometer materials – graphite filling is far smaller than the pure PTFE composite materials, nano – graphite filled PTFE material can improve the wear resistance. That the essence of wear about PTFE under the action of external force, macromolecular chain will slip or rupture, so that the material is pulled out of the land of crystalline region and the slice on the surface of the transferred to accidentally, caused by adhesive wear. Due to the hardness of PTFE and the shear strength is lower than metal, with the steel mill, PTFE wear mainly in itself. After PTFE filled with nano – graphite composite material, its hardness, compressive strength, elastic modulus and creep performance are improved, when its contact with the metal surface, packing plays a role of bearing load, PTFE macromolecular implicated by padding at the same time, it is not as easy as in the filled PTFE relief, and obviously improve the wear resistance.

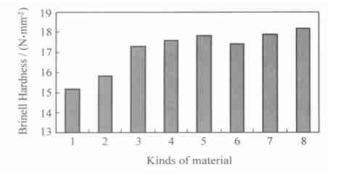

Figure 2 is the rigidity of PTFE and nano graphite filled composite materials, we can find that, nano materials and nano – graphite filled PTFE material can improve the hardness, the hardness of PTFE composites increase will make its wear resistance also increase. Nano material filling and its corresponding nano – hardness of mixed graphite filled PTFE composites were similar, three kinds of nano – graphite filler material, nano – SiO2 – graphite materials to improve the hardness of PT FE is more, so its corresponding wear ability is good, and nano – PT FE Al2 O3 – graphite composite materials is small, therefore, the hardness of the PTFE composite material has smaller, wear ability is poor, which further shows that nano – graphite is mixed filling materials have played a role in bearing load.

Figure 2 PTFE, nanometer material and its hardness with graphite filled PTFE composite material

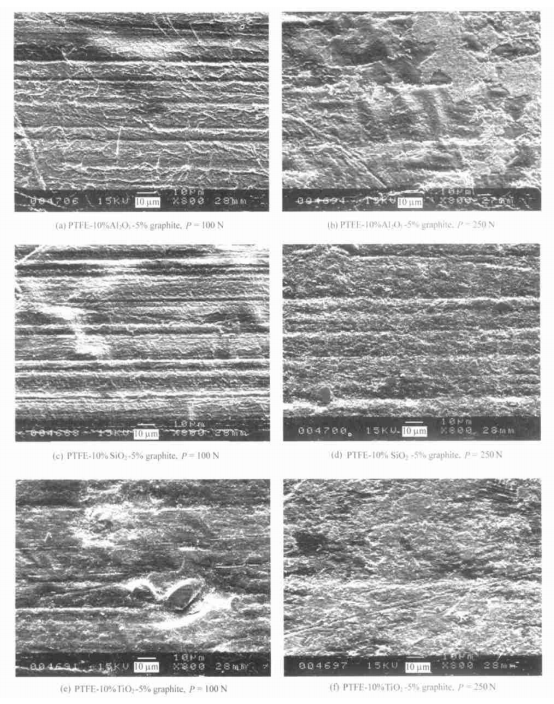

Figure 3 shows three different nanometer materials and graphite filled PTFE samples under two load worn surface morphology of the SEM. It can be seen that different nano – almost the wear surface of graphite filled PTFE has different degree of furrows and plastic deformation, and furrows and plastic deformation degree and the filling material and the size of the load, the load is small (100 N), furrows and plastic deformation are relatively mild, and can see the wear and sliding in the same direction, their gall scratches relatively clear [figure 3 (a), 3 (c), 3 (e)];When load increases, furrows and plastic deformation are aggravating, especially nano Al2 O3 – graphite filled PTFE, when load increases, the sample the furrows of the SEM photos visible on the surface of the larger, and appeared surface flaking off, show the characteristics of fatigue wear. And nano SiO2 – graphite mixed filling materials, when the load increases (250 N), the surface is still visible, which is similar to those of low load and grinding crack, explain the material in the loading load range is not sensitive to loading, from the previous figure 1 also shows that load increase the added value of this kind of composite material the erosion rate is very small, showing good abrasion resistance. Also can be seen from the picture, in three groups of filling material, nano SiO2 – graphite mixed filling materials in load under the action of wear and tear, and the plough cut effect of plastic deformation is small, so the nano SiO2 – mixed graphite filled PTFE composites showed better resistance to wear, mixing of nano SiO2 – graphite filler material is one of the effective material of PTFE improve wear resistance.

Figure 3 SEM photographs of worn surfaces of PTFE filled with different nano – materials and graphite

Friction performance

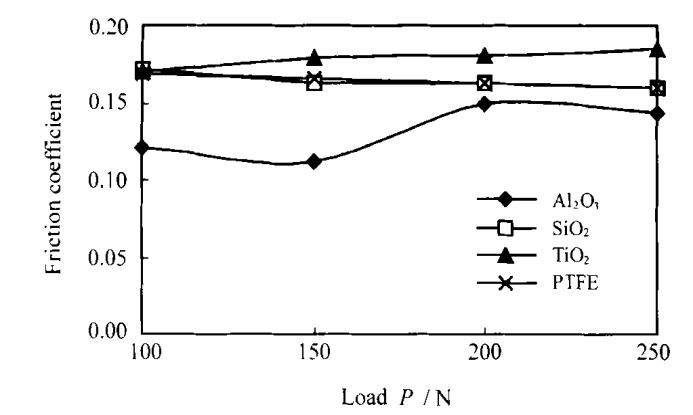

Figure 4 shows the PTFE and different nanometer materials – graphite filler PT FE composite friction coefficient along with the change of load. It can be seen that different nano – graphite material for PTFE composite material with different friction coefficient, the influence of different nano – graphite filled PTFE composite material of the friction coefficient with the increase of load are different. Nano SiO2 – graphite filler PTFE composite materials and PTFE are basic same, friction coefficient and load increase slightly to reduce the friction coefficient, and nano TiO2 – graphite filled PTFE composites slightly bigger than a pure PTFE friction coefficient, and slightly increased along with the increase of load, nano Al2 O3 – graphite filled PTFE composite material is smaller than the pure PTFE, its relationship with load is more complicated. All in all, three kinds of nanometer materials – mixed graphite filled PTFE composite, the friction coefficient of nanometer Al2 O3 – graphite filling PTFE composite material is smaller than the others, nano TiO2 – graphite filled PTFE composite material of the friction coefficient is bigger, the corresponding relationship between the abrasion performance above, nano – SiO2 – wear resistance of graphite filled PTFE composites is much better than nano Al2 O3 – graphite filled PTFE composite material, it shows that SiO2 – graphite filler mixed filling materials for PTFE is a kind of good filling material, its wear resistance of PT FE increased significantly, and the coefficient of friction and pure PT FE are basic same. Although nano Al2 O3 – graphite mixed filling materials can reduce the friction coefficient of PT FE, to improve the wear resistance of PT FE is worse than SiO2 and TiO2 – graphite – graphite filled PTFE composite material performance.

Figure 4 The relationship between load and friction coefficient of different nanometer materials filling PTFE

Conclusions

(1) Nano- graphite mix packing and can improve the hardness and wear resistance of PTFE, they improve the wear resistance of the reason is because the filler material bearing load and graphite lubricant and the three kinds of nano – graphite filled PTFE composite material, mixed with SiO2 – graphite filling effect is best, its wear resistance of PTFE increased more.

(2) Different nano – graphite filled PTFE composite material is different, the friction coefficient of nano SiO2 – graphite friction coefficient of PTFE composites filled with PTFE is basically the same, the friction coefficient of nano TiO2 – graphite filled PTFE than pure PTFE increases slightly, and nano Al2 O3 – graphite filled PTFE composite material is smaller than the pure PTFE.

If you need more information about our products, please contact us: infocorefrp@gmail.com ,our engineers will answer you and provide free samples.